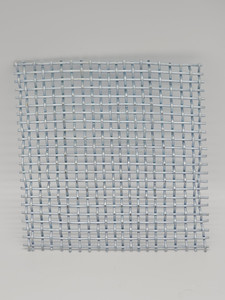

Fire Brick.

A fire brick is a dense, heat-resistant brick used in jewelry making for soldering, annealing, and other high-temperature processes. The brick can withstand temperatures up to 2600°F (1427°C), making it an essential tool for jewelry makers who work with metals.

The best uses for a fire brick in jewelry making include:

-

Soldering: A fire brick can be used as a soldering surface, providing a heat-resistant work area for soldering jewelry pieces together.

-

Annealing: Jewelry makers can use a fire brick to anneal metals, which involves heating the metal to a high temperature and then allowing it to cool slowly. This process can help soften the metal, making it easier to work with.

-

Torch firing: Some jewelry makers use a fire brick as a surface for torch firing enamels onto metal pieces.

-

Metal clay work: Fire bricks can be used as a surface for working with metal clay, providing a heat-resistant work area for shaping and firing the clay.

Some unique uses for a fire brick in jewelry making include:

-

Creating textures: Jewelry makers can use a fire brick to create unique textures on metal surfaces. By pressing metal pieces onto the rough surface of the brick, makers can create a variety of patterns and designs.

-

Wax carving: Fire bricks can also be used as a surface for carving wax models for jewelry pieces. The heat-resistant surface helps prevent the wax from melting or deforming during the carving process.

Overall, a fire brick is a versatile tool that can be used in a variety of ways in jewelry making, making it an essential item for any jewelry maker's tool collection.